Temperature adjustment method of oil-immersed transformer

2023-03-02

In order to further improve the air-drying quality of the rotor winding of oil-immersed transformer, there are two factors that should be carefully and comprehensively considered: one is to control the drying temperature; Second, improve the vacuum value of facilities and equipment. General drying machinery can ensure the production process requirements. For the second point, due to the adverse effects of many factors, it is necessary to consider comprehensively and scientifically to obtain a better drying prediction.

In the process of vacuum preservation during drying, it is not suitable for vacuum preservation or drying under the condition of low mechanical pump in the relatively low temperature stage of slowly drying. Otherwise, it is not good for improving the working temperature of oil-immersed transformer coil and eliminating cold and humidity. When the working temperature rises to 70~80 ℃, slowly increase the vacuum pump value.

When drying for 1~2h, there is more water vapor in the oil tank, the ability of radiant heat work is improved, the working temperature of the internal structure tends to be uniform, the moisture also gradually decreases, and the professional ability of radiant heat is reduced. The method for identifying the insulating tube after drying and the performance parameters of the oil transformer.

Working temperature is an externally standardized definition. For the ecological environment protection of oil-immersed transformer operation, it is damaged and restrained by working temperature. Without high quality working temperature, oil-immersed transformer cannot be driven to operate with high quality. As for the working temperature of oil-immersed transformer, it not only determines the operation of oil-immersed transformer, but also endangers the service life of oil-immersed transformer. Therefore, it is important to grasp the working temperature of oil-immersed transformer. Operate the oil-immersed transformer at the proper working temperature, which is beneficial to improve the service life of the oil-immersed transformer. What is the relationship between them?

For the installation of oil-immersed transformers in power equipment, most of them choose tinfoil insulating sleeves, namely, Class A cable sheaths. For the oil-immersed transformer with Class A grounding wire resistance, the standard value of the winding resistance of the oil-immersed transformer is 105 ℃ when the working temperature of the surrounding gas is 40 ℃ during normal operation.

Social practice and research have found that if the winding resistance can maintain the operating temperature of 95 ℃ continuously, it can ensure that the oil-immersed transformer has a 20-year application period. According to the relationship between the working temperature and time, we can also draw a commonly said 8 ℃ law: with the service life above the working temperature as the majority, the use of oil-immersed transformer will be reduced by 1/2 every 8 ℃ rise in the winding resistance working temperature.

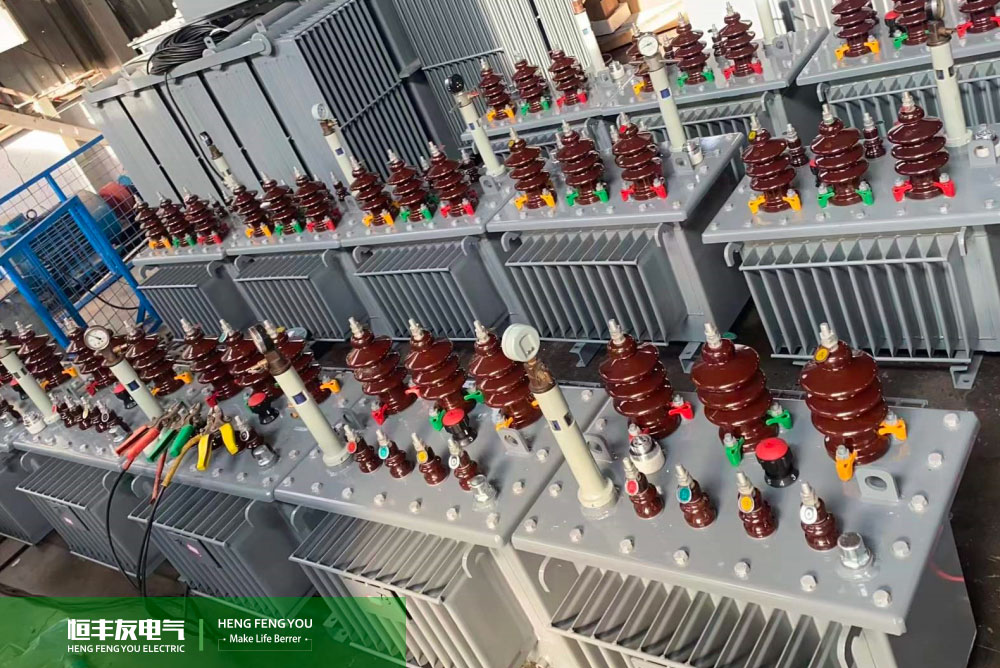

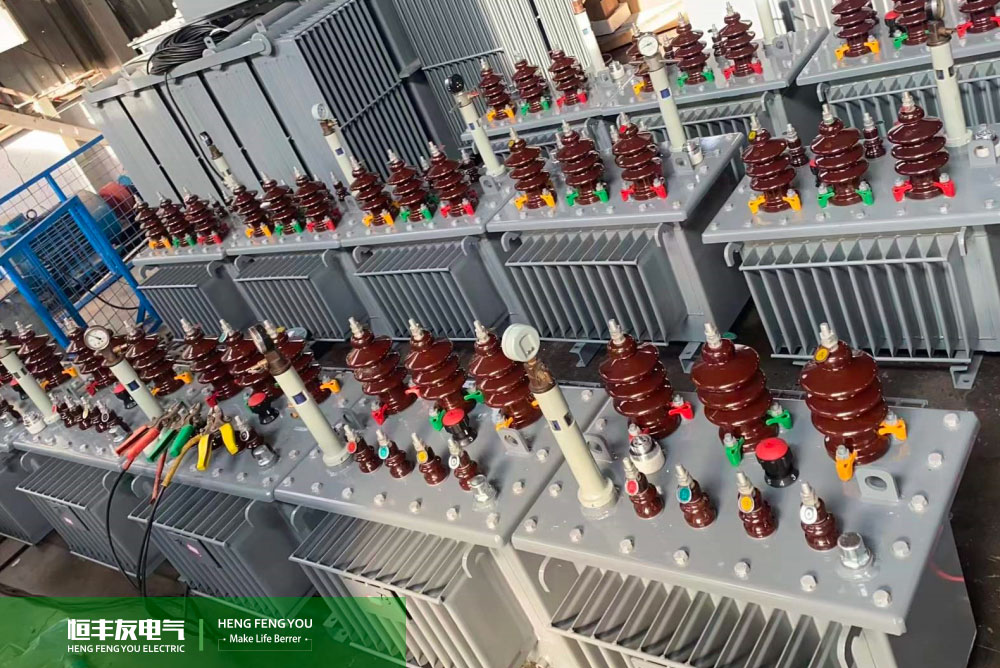

Qingdao Hengfengyou Electric Group, is an electrical enterprise with transmission and distribution industry as its main business, integrating product research and development, manufacturing and trade. Designated suppliers for the world's top 500 enterprises.Its main products include oil-immersed transformer,dry-type transformer,electric furnace transformer,mining transformer ,rectifier transformer .It has been successfully sold to more than 50 countries around the world. Product certification is complete. Hengfengyou Electric will provide you with the best electrical product solutions. 【https://www.hengfengyou-electric.com ; sales@hengfengyou-electric.com ; WhatsApp:+86158 5325 2696(Jack) 】

Send a message to the supplier